Laser cutting

The basis of the cutting system is a laser beam source, which is led through an optical cable or a system of mirrors to the cutting head carried on the portal of the cutting table. In the cutting head, the beam is focused into a technologically precisely defined focal length depending on the type and thickness of the material. However, with the increasing thickness of material, its accuracy decreases. Not every material can be cut by laser. For example, copper, when heated, reflects the laser beam and thus makes it impossible to liquefy and blow away. Either materials whose heating releases toxic fumes as for example galvanized sheet metal.

No consumables are used in laser cutting, except of the supplied auxiliary gases, which are driven into the active cut to increase the efficiency of the application and maintain the quality of the cut.

According to the protective gas used, cutting is divided into:

- MELTING

- assistance gas - nitrogen

- pure non-oxidized glossy cuts

- OXIDATIVE

- assistance gas - oxygen

- cuts with a noticeable trace of oxidation

The principle of laser is to convert electrical energy into light energy, so its consumable is only electricity.

KIMLA PowerCut Fiber linear

Technical parameters of laser cutting

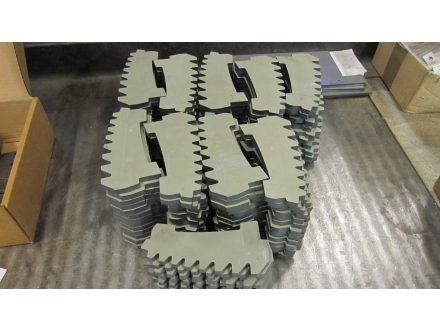

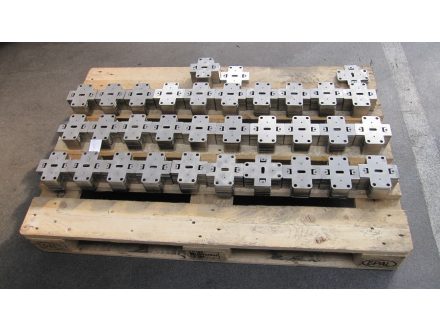

- thickness of the split material from 1 to 15 mm including (structural steel)

- thickness of the split material from 1 to 10 mm including (stainless steel)

- thickness of the split material from 1 to 6 mm including (aluminium)

- working area 3000x1500 mm

- product accuracy ± 0.1 to 0.5 mm